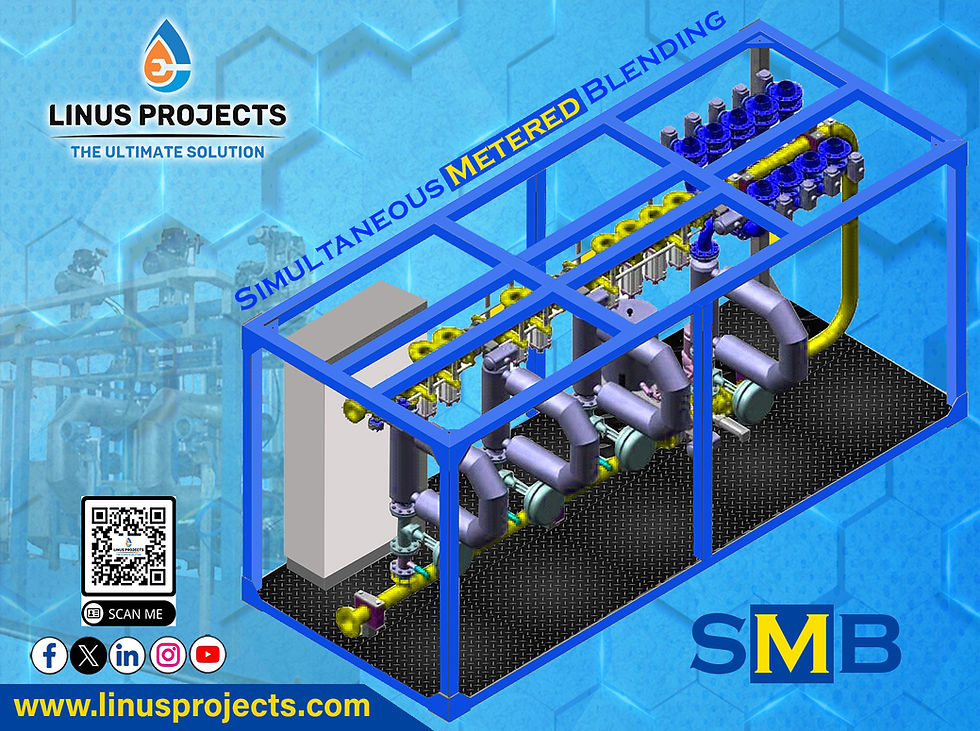

SIMULTANEOUS METERED BLENDING (SMB) Lubricants & Greases Manufacturing Solutions

- LINUS PROJECTS

- Aug 4, 2023

- 2 min read

Simultaneous Metered Blending unit (SMB) are a turnkey blending system it’s much more advanced system of processing lubricants and greases manufacturing plants It’s a combination of high volume production capacity of In Line Blending units (ILB) with operating flexibility of Automatic Batch Blending (ABB) Instead of blending in a kettle Components are simultaneously dosed into a header before discharging to tank for final mixing. SMB systems are engineered to concurrently gauge liquids using a Coriolis flow meter and ensure their precise proportional mixture via a central conduit. These Simultaneous Metered Blenders are compact modular setups that employ Micro Motion technology for accurate measurement and control. They function by accurately dispensing the appropriate proportions of various components into the central conduit, which then directs the blended mixture for subsequent homogenization.

Benefits of Simultaneous Metered Blending Unit (SMB)

1. Dosing is done at faster speeds and with higher accuracies. Accuracy not limited by batch size.

2. Mass flow measurement

3. Improve installation flexibility with compact skid.

4. Reduce cross-contamination it is possible to correct the blend by dosing small quantities of the balancing material. Minimum contamination with pigging and flushing.

5. Efficient for any blend size - limited only to size of destination tank.

6. Increases Blend capacity and efficiency compared to traditional batch blending method.

7. Generate zero slop or waste fluids, decrease overall mixing time.

Linus Projects (India) possesses a comprehensive grasp of the intricacies involved in operating lubricating oil and grease manufacturing facilities. The company excels in optimizing production efficiency while minimizing expenses, having successfully executed numerous comprehensive blending projects utilizing ABB and ILB systems. Linus Projects has also undertaken extensive plant upgrades on a global scale. The SMB approach seamlessly merges the substantial high-capacity production capabilities inherent in inline blending units (ILB) with the adaptable operational features of ABB's automatic bath blending. The entirety of this process is under the precise control of a PLC system, complemented by a sophisticated recipe management system. The control system can also auto perform automated pigging control and bulk inventories, laboratory data handling. Reduces installation costs time and contamination. Collaborating with Linus Projects (India) you can incorporate with latest technology in processing Lube Oil Blending Plant (LOBP) business.

Comments