GREASE MANUFACTURING PLANT

INTRODUCTION:

We are experienced manufacturers and suppliers of grease manufacturing plant equipment in India and worldwide. Our goal is to provide world-class service through innovative, reliable manufacturing and supply of specialised high-end products. Our team is always ready to assist you with equipment designed for your specific requirements.

What is Grease?

Grease is a solid or semisolid lubricant formed as a dispersion of thickening agents in a liquid lubricant. Grease generally consists of a soap emulsified with mineral or vegetable oil.

A common feature of greases is that they possess a high initial viscosity, which upon the application of shear, drops to give the effect of an oil-lubricated bearing of approximately the same viscosity as the base oil used in the grease. This change in viscosity is called shear thinning. Grease is sometimes used to describe lubricating materials that are simply soft solids or high-viscosity liquids, but these materials do not exhibit the shear-thinning properties characteristic of classical greases. For example, petroleum jellies such as Vaseline are not generally classified as greases.

Greases are applied to mechanisms that can be lubricated only infrequently and where a lubricating oil would not stay in position. They also act as sealants to prevent the ingress of water and incompressible materials. Grease-lubricated bearings exhibit greater frictional characteristics due to their high viscosity.

Properties of Grease:

True grease consists of an oil and/or another fluid lubricant that is mixed with a thickener, typically a soap, to form a solid or semisolid. Greases are typically shear-thinning or pseudo-plastic fluids, meaning that their viscosity decreases under shear. After sufficient force to shear the grease has been applied, the viscosity drops and approaches that of the base lubricant, such as mineral oil. This sudden drop in shear force indicates that grease is considered a plastic fluid, and the reduction in shear force over time makes it thixotropic. A few greases are rheotropic, meaning they become more viscous when worked. It is often applied using a grease gun, which applies the grease to the part being lubricated under pressure, forcing the solid grease into the spaces in the part.

Thickeners:

An inverse micelle is formed when soap is dispersed in an oil. This structure is broken reversibly upon shearing the grease.

Soaps are the most common emulsifying agents used, and the type of soap selected is determined by the application. Soaps include calcium stearate, sodium stearate, and lithium stearate, as well as mixtures of these components. Fatty acid derivatives other than stearates are also used, especially lithium 12-hydroxy stearate. The nature of the soap influences the temperature resistance (related to viscosity), water resistance, and chemical stability of the resulting grease. Calcium sulphonates and polyureas are increasingly common grease thickeners not based on metallic soaps.

Powdered solids may also be used as thickeners, especially as clays. Fatty oil-based greases have also been prepared with other thickeners, such as tar, graphite, or mica, which also increase the durability of the grease. Silicone greases are generally thickened with silica.

Types of Grease:

Grease is classified into two classes

A) Soap type grease:

In this type, we prepare soap first and then mix it with base oil to formulate the grease. Below are the type of grease that comes in this class.

1. Lithium Grease

2. Calcium Grease

3. Aluminium Grease

4. Lithium Complex Grease

B) Non-Soap type Grease:

1. Urea Grease

2. Synthetic Grease

3. Bentonite Grease

Additives:

Some greases are labelled "EP", which indicates "extreme pressure". Under high pressure or shock loading, normal grease can be compressed to the extent that the greased parts come into physical contact, causing friction and wear. EP greases have increased resistance to film breakdown, forming sacrificial coatings on the metal surface to protect if the film does break down, or include solid lubricants such as graphite or molybdenum disulfide to provide protection even when no grease remains.

Solid additives, such as copper or ceramic powder, are added to certain greases for use in high-pressure and/or high-temperature applications, or where corrosion could prevent the disassembly of components later in their service life. These compounds are working as a release agent. Solid additives cannot be used in bearings due to their tight tolerances. Solid additives will cause increased wear in bearings.

GREASE MANUFACTURING PLANT & MACHINE

01.

FILTRATION SOLUTION

02.

PROCESS

03.

UTILITY

04.

FILLING LINE

05.

AUTOMATION

01. PUMPING & FILTRATION SOLUTION

THE PUMPING SOLUTION:

Avoid costly downtime and keep your machine running at its peak performance with our gear pump for lubricant dosing inside the Grease kettle.

The three-piece design makes the pump easily cleanable and maintainable. Cleaning of the aerator and suction arm can now be done without first removing the cover. Even more importantly, it is possible to replace worn-out parts.

The Pump is equipped with a mechanical seal. The mounting bracket converts the pump to foot mounting & facilitates aligning the pump with the electric motor of appropriate ratings on the base plate at the same frame height.

The feed rate for the base oil pump will be around 20m3/hr to 50m3/hr at a pressure of 4 Bar to 10 Bar

THE FILTRATION SOLUTION:

Unfiltered liquid enters the basket housing and passes down them.

Solids are retained inside the basket mesh, which is removed during servicing of the unit.

Basket Filters and strainers are generally supplied with a spring arrangement at the top of the filter element.

This will ensure any type of bypass & confirm the position of the basket filter even in case of reverse flow.

A fluid bypass around the basket is prevented by an optional “O” ring seal between the basket rim and the housing inside diameter.

For the base oil basket filter provided with a 200-micron mesh, and for the blending vessel basket filter provided with a 50-micron mesh

02. PROCESS

GREASE KETTLE (REACTOR):

Linus Projects is an Indian manufacturing company with a board-level management team that boasts a wealth of experience in engineering, design, and manufacturing. We supply selected engineering products to meet the demand at the bottom line.

The Process Equipment People designs, engineers, and manufactures the Double Motion Grease Kettles, which are extensively used in the production of lubricating greases for automotive, aircraft, railroad, and industrial applications.

Linus Projects Supply mainly three types of grease kettles (Reactor)

-

Pressure Kettle(Reactor)

-

Non Pressure kettle(Reactor)

-

Bottom Conical Kettle (Reactor)

Pressure Kettle(Reactor):

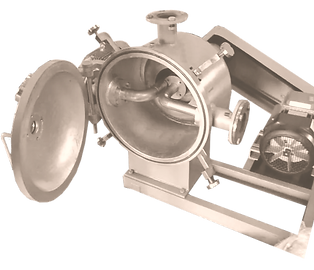

Double Motion Counter - Rotating Agitator Stirrer, consisting of a stationary, mounted drive Assembly and a Grease Kettle Body that can be manually raised and lowered. A flush-bottom handwheel-operated Discharge/Sampling Valve is located on the Kettle's bottom.

Our Kettle is an Autoclave-type Pressurised 6 kg Working capacity. The Kettle comes complete with a double-motion counter-rotating agitator stirrer, essentially consisting of a Stationary-Mounted Drive Assembly and a Grease Kettle Body that can be manually raised and lowered, similar to a Drill Press Arrangement.

A kettle consists of two dishes and a shell. The bottom dish is equipped with a flush-bottom discharge valve. The agitator assembly consists of a simplex-designed system where shafts fitted with agitators thoroughly blend the grease and move the entire mass. Scrapers are provided at the sides and bottom of the agitator assembly.

Non Pressure kettle(Reactor):

A kettle consists of a base, a shell, and a lid. The bottom dish is equipped with a flush-bottom discharge valve and a ball-type drain valve for sample removal, testing, and verification. The agitator assembly consists of a simplex-designed system where shafts fitted with agitators thoroughly blend the grease and move the entire mass. Scrapers are provided at the sides and bottom of the agitator assembly.

Bottom Conical Kettle (Reactor)

The Autoclave-Style Grease Kettle can be used for the complete grease manufacturing cycle - saponification, grease finishing, and cooling. However, the processing time is extended when compared to saponification being performed in a Linus Projects Grease Base Reactor. The Reactor, with its jacketed vessel construction—encompassing jackets over both the shell and cone sections—and a double-wall inner circulation tube, offers a significantly increased surface area for transferring heat to the soap. Coupled with this is the dramatically increased rate of product circulation brought about by the bottom propeller agitator that operates at full or half motor speed. This type of agitation/mixing action ensures a homogeneous soap base for transfer to the Grease Finishing-Cooling Kettle, where the balance of oils and additives is charged and the final grease product is manufactured.

GREASE MILLING AND DEAREATION SYSTEM

WHAT IS A GREASE MILLING DEAREATING SYSTEM?

The Grease Milling and Deaerating System is Equipment in the Grease manufacturing process, designed specifically for refining and enhancing the quality of grease formulations. This integrated system combines milling and deaeration processes, ensuring the uniformity, consistency, and removal of entrapped air in the grease product.

A. Grease Milling Machine:

The up-and-down Colloid Mill is ideal for fine grinding, breaking up, and blending, all of which can be achieved in a single operation. The Mill consists of an SS 304 water-cooled jacketed mill housing, inside which is fitted a 3-stage Rotor and Stator group of devices made up of smaller parts. The material is pumped into the mill and is forced to shear, breaking up and moving away, mixing & and blending very well. The rate and degree of the above process can be finely controlled manually during operation by adjusting to make better/changing to fit new conditions, such as the gap between the rotor & stator. All rotating parts are balanced and well-oiled/greased for trouble-free operation. The shaft is installed in a leak-proof housing complete with bearings, O-rings, and oil seals. The electric motor gave/given is of 30 HP, 3000 RPM

B. Deareator Assembly:

A Deaerator is equipment that eliminates gases and moisture from semi-fluids and fluids. Deaerators are ordinarily used to eliminate oxygen, trapped air bubbles and dissolved gases in oil. The air pockets and gases in oil will genuinely harm the quality and life of Grease. Deaerator is utilised in the Grease Manufacturing Plant frequently.

Deareator features:

-

Eliminates the caught air and bubbles inside the oil or jam item

-

Effective blending, homogenising the oil.

-

Expulsion of dampness or refining of residuals under specific conditions.

C. Vacuum Pump for Deareator:

A vacuum pump is a device that draws gas molecules from a sealed volume, leaving behind a partial vacuum. The job of a vacuum pump is to generate a relative vacuum within a capacity. The first vacuum pump was invented in 1650 by Otto von Guericke and preceded the suction pump, which dates back to antiquity.

GREASE HOMOGENIZER

A grease homogenizer is an industrial machine specifically designed for the production and processing of grease, ensuring a uniform texture, consistent quality, and stable emulsification of its components.

Grease is a combination of oils, thickeners, and various additives that require accurate blending to reach the desired consistency and performance attributes.

The homogenizer performs this task by applying high-shear forces that break down particles and distribute them uniformly throughout the mixture.

This process is essential for forming a uniform structure in the grease, which is vital for its lubrication properties, thermal stability, and resistance to water and oxidation.

SLURRY MIXER

Slurry mixers play a vital role in the grease manufacturing process by ensuring thorough and efficient mixing of base oils, thickeners, and additives to create high-quality grease products. In a grease manufacturing plant, slurry mixers are used to

-

Homogenize Ingredients:

The mixer evenly blends oils, soaps, and other thickening agents to ensure a uniform consistency in the grease. -

Maintain Product Consistency:

Proper mixing ensures that the final grease product has the desired texture, performance characteristics, and stability, preventing ingredient separation. -

Improve Efficiency:

Slurry mixers are designed to handle high-viscosity materials, which is crucial in the production of grease. They reduce mixing time and energy consumption while enhancing product quality. -

Handle High-Temperature Operations:

Many grease formulations require elevated temperatures to facilitate chemical reactions. Slurry mixers can operate under these conditions, ensuring the mix is heated uniformly without localised overheating. -

Scalability:

From pilot plants to full-scale production, slurry mixers are available in various capacities, allowing for flexibility in production volumes.

BOILER FOR UTILITY PURPOSE

Linus Projects supplies high-quality, fuel-efficient burners for boilers that operate with both steam and thermic fluid.

The main heater unit consists of a double-jacketed external shell made of sturdy MS sheets, with an aluminium reflector to preheat the combustion air and provide heat insulation.

Specially designed multi-start, concentric helical coils assembly made from B.S 3059,

Part I, 9-Gauge Boiler Tubes for longer life and high-temperature operations.

Pressure jet burner assembly on/Off Design, make – RIELLO –ITALY, with integral Oil Pump & Combustion blower assembly with the motor.

03. UTILITY

GREASE DRUM DECANTING UNIT

A Grease Drum Decanting Unit is an advanced piece of equipment intended for the effective and precise transfer of grease from large drums to smaller containers or dispensing units. It enhances the decanting process while ensuring accuracy, safety, and minimal grease loss.

Typically, a grease drum decanting unit consists of a robust framework or base that securely holds large grease drums for decanting. This unit is specifically designed to fit standard-sized grease drums, which usually have capacities ranging from 50 kg to 200 kg. It may feature adjustable drum clamps or cradles to ensure stability throughout the decanting process.

STRUCTURAL SOLUTION:

The Platform structure design for Grease Kettle.

The steel structures can be created in a wide range of shapes and sizes, are designed for both short-term and long-term use, and can serve as either temporary or permanent structures.

They are made from standard rolled and cold-formed steel sections, which are reinforced using stabilising rods with tensioners.

In order to use the platforms, it is necessary for the space to have a height of at least 5meters. Our design has a minimum ceiling height of 2.1 meters.

It is possible to equip the platforms with various accessories, such as elevators, chutes, mesh, labels, lighting, etc.

CLOSED CIRCUIT COOLING TOWERS

Hot Oil cooling framework comprising S.S. cooling loops made out of S.S. consistent lines. The curls are properly moved at a nearby pitch for productive cooling. The pitch, stature, and breadth of the curls are intended for speedy and effective cooling of the pots. The loops are clipped onto a sturdy primary stand made from welded steel segments.

A cooling tower of suitable size will be provided alongside GI louvres made out of GI sheets. The supporting construction is produced using substantial moved steel areas. At the top of the pinnacle will be a GI line header with branch headers fitted with gunmetal shower spouts.

A monoblock siphon shaving release limit of 1,500 litres per minute at a 15 m head will be provided. All the underlying stands and GI louvres will be set apart for a simple get-together at the site. The cooling pinnacle will be provided without the base stockpiling bowl; however, it will include any remaining designs. The framework is complete with one 1000-litre cold oil storage tank, a 1000-litre development tank, and a 10 m³/hr oil transfer pump of 3 HP.

INSULATION MATERIAL FOR HEATING LINE:

Linus Projects supplies high-quality Rockwool and aluminium sheet, along with the plant for insulation of hot oil lines and blenders, etc.

All insulation shall be installed using a ROCKWOOL mattress 50 mm thick, as required, with a density of 100 kg/m³, of a reputed make, and clad with an aluminium/GI sheet of 24 gauge. This part of the job must be performed on-site. The material shall be supplied loose, and the client must organise it at the site under our guidance.

Insulation of pipelines below blenders to filling lines to be done on-site.

GREASE PACKAGING SOLUTION

A.GREASE FILLING MACHINE:

Fillers (or Grease filling machines) are used for packaging, primarily for food/beverage, but also for other products. These are used to fill either a bottle or a pouch, depending on the product.

The packaging industry utilises several types of fillers. The type of Food or beverage filling machines to be used is usually determined by the kind of product to be filled, speed requirements, quality, shelf life expectations, resource availability, technology feasibility, and many other variables. The type of food products may range from solid to semi-solid, from liquid to frozen, from hot to cold, from free-flowing to highly viscous, and so on. This wide range of product characteristics also suggests that filling machines with great flexibility and versatility are the most valuable. There are various filling technologies for liquid and dry products, and product filling machines can be rotary or inline, with intermittent or continuous motion, and semi-automatic or fully automatic. These machines utilise various filling technologies to cater to the vast range of product variables and user requirements, each offering unique advantages.

The following are the most common:

-

Auger/agitator fillers: designed to fill dry mixes, such as flour and sugar. The fillers have a hopper shaped like a cone that holds the mix and dispenses it into a pouch using an auger conveyor controlled by the agitator. The mix is filled into a pouch made of paper or poly, which is then formed into a collar. A series of heaters seals the pouch and dies. The interface with the process supplying the powder is of prime importance to ensure an efficient filling.

-

Vibratory weigh fillers: provide you the perfect blend of accuracy, speed, and versatility across a comprehensive line of linear feeders. Every weighing hopper is designed to handle the unique needs of precise weights.

-

Flow fillers: designed for liquids, oils, and thin food products. These fillers are designed so that when they fill a bottle or tub that enters the machine, they eject the open bottle back onto another conveyor for sealing.

-

Tablet fillers: These are designed for products that are counted by pieces instead of weight. These are designed for small bottles (similar to some of the flow fillers), but the hopper of the filler is set up to permit scan counting of tablets or candy pieces.

-

Positive displacement pump fillers: positive displacement, pump filling machines easily handle a wide range of container sizes, fill volumes, and product types. While initially designed for filling creams, gels, and lotions, these fillers also handle water-thin and heavy paste products. Some of the products this machine can easily fill are cosmetic creams, heavy sauces, thick shampoos and hair conditioners, honey, hair gels, paste cleaners, and car wax.

-

Tube filling machinery: Tubes typically contain viscous products and require specialised filling equipment.

-

Vertical form fill sealing machine: A vertical form fill sealing machine is a type of automated assembly-line product packaging system, commonly used in the packaging industry for the food and Grease industry.

-

Drum Filling Machine: The Drum Filling Machine is designed to accurately fill large drums with grease, guaranteeing both precision and consistency. This equipment is utilised in various packaging solutions, enhancing bulk packaging processes while steadfastly maintaining the brand's renowned high-quality standards.

04. FILLING LINE

B.GREASE CAPPING MACHINE:

The machine comprises a Cap Vibrator for cap orientation & a capping unit.

The caps are correctly oriented in the vibratory hopper.

The properly oriented caps are brought out through the chute and supported at the end by spring-loaded fingers. The containers, as they exit the filling station, proceed to the capping unit, where they pick up the cap and are directed towards the capping head.

The caps are subsequently tightened through a magnetic clutch system. The capped bottles finally emerge from the machine through a discharge conveyor.

The speed can be adjusted through the VFD on the conveyor. A necessary mechanism shall be provided for 'no bottle-no cap'. The torque can be set on the PLC of the filling machine.

C. AUTOMATIC INDUCTION SEALING MACHINE

The technology of heating and sealing the aluminium-plastic multiplex material using an electromagnetic induction sealing machine, manufactured according to this principle, has become a necessary piece of equipment for the pharmaceutical, pesticide, high-quality viscous oil, cosmetics, grease, and other industries that require high-quality air sealing for plastics and other non-metallic bottles.

The latest I.G.B.T. Solid State Induction Cap Sealing System Model LP-2 for neck size up to 38mm is suitable to seal 70 to 80 bottles per minute, and for a neck range, up to 53mm is suitable for 40 to 50 bottles per minute.

Working principle: The Machine is based on the principle that a metal object can generate a blow wave to heat it under the action of a high-frequency electromagnetic field. Making aluminium foil hot and melting the binding under aluminium foil, then agglutinating to the mouth of the bottle, thus accomplishing the constant, quick, non-contact sealing operation.

D. LABELLING MACHINE:

A labelling machine significantly boosts the visual presentation of products and is crucial for effectively communicating key information to consumers.

This machine is expertly designed for high-speed applications, ensuring that grease containers are labelled swiftly and efficiently.

The Labelling Machine's seamless integration with printing systems facilitates the inclusion of important product details, such as batch numbers, expiry dates, and other regulatory information. With its user-friendly controls, operators can conveniently adjust settings for label size, placement, and speed, which enhances the machine's overall functionality.

E. BATCH CODER / LASER PRINTER:

Engineered by Linus Projects, the Laser Printer plays an important role as a fundamental component. It achieves high-resolution printing, which guarantees the production of clear and easily readable markings on containers of lubricating oil. The Laser Printer features a synchronized printing process that fits perfectly within the overall production line.

The Laser Printer is equipped to handle variable data printing, which allows for the customization of each print with dynamic information such as batch numbers, production dates, and other relevant details.

F. CARTON TAPPING SOLUTION:

Linus Projects supplies sophisticated design carton-taping machines. The Carton Taping Machine is put on the in-feed rollers & given a gentle push when the motorised conveyor takes over & starts pulling the carton forward. Here, the top & bottom tape dispensers simultaneously stick the BOPP-type self-adhesive tape onto the top and bottom flaps of the cartons, while rollers press the tape for a tight seal. When the taping is over, the cutter blades cut off the tape & the sealed cartons pass through to the outfeed rollers for delivery.

We are offering a Regular Carton Sealing Machine. These are designed and manufactured under the supervision of our professionals, using high-grade quality raw materials in adherence with industry standards. The offered machines are widely used for packaging boxes of various sizes and shapes.

Features:

Low maintenance, high performance, and Corrosion resistance with a longer functional life.

LOAD CELL: METTLER TOLEDO BRAND

The blending vessel is equipped with a high-quality, precision load cell system, which is suitable for automatic performance and batch control of the plant, typically utilising ABB technology.

A load cell has the following advantages.

-

Built-in Safety against vessels tilting and building forces

-

Allows vessels to expand and contract, which occurs due to the thermal effect.

-

Flexible copper earthing strip to protect the load cell from lightning or welding current

-

Built-in Load Cell cable protection plate & Overload protection plate with Heat Insulation Pad.

05. AUTOMATION

ELECTRIC AND AUTOMATION PANEL FOR PLANT

A. ELECTRIC MOTOR CONTROL PANEL:

MCC stands for motor control centre. It consists of feeders for motors and blowers. Feeders are designed according to the motor rating. In most MCCs, auto/manual provision will be available. With manual provision, motors can be operated manually. An external signal is required to start the motor for auto-provision. The control panel gives the signal. Indicators for motor operation will also be displayed on the control panel.

A motor control centre (MCC) is an assembly of one or more enclosed sections having a common power bus and principally containing motor control units. Motor control centres, in modern practice, are typically factory-assembled units comprising several motor starters. A motor control centre can include variable frequency drives, programmable controllers, and metering, and may also serve as the electrical service entrance for the building.

The panel accommodates working with all of the electrical engines. The board is properly pre-wired and encased in a sheet steel powder-covered walled-in area. An MCC board gave a far-off press button Station to control the engine. Every one of the engines is controlled through the MCC board. If anything goes wrong with the engines, the board will trip to protect the engine from harm. The board is given a decent brand of switches Like L&T etc.R-Y-B lights with Ammeter and voltmeter advanced sort is given. An electrical control board is used to control all of the electrical engines. The board is properly pre-wired and encased in a sheet steel powder-covered fenced-in area.

B.AUTOMATION PANEL:

Automation panels combine the functions of a programmable controller and operator interface into a single unit. Automation panels, such as GE's QuickPanel, reduce hardware costs by combining the controller, operator interface, and remote connectivity into one device.

A total PLC-based SCADA is accommodated, observing and controlling the progression of base oils to the Blenders. A formula is provided to execute the framework, capable of handling up to 100 recipes.

ADVANTAGES OF OUR AUTOMATION PANEL:

Automation panels combine the functions of a programmable controller and operator interface into a single unit. They came on the market about 15 years ago. Many early units were simply OI panels with some local IO, ladder logic, and a flat database. Modern panels, such as GE’s QuickPanel+, incorporate the full suite of IEC 61131 programming languages (ladder, structured text, function block diagram, sequential function chart, and instruction list), as well as user-defined data structures and function blocks.